RCPP Irrigation Hydro Resources

Technical Service Providers | Partners

Technical Service Provider Resources

Register as a Technical Service Provider

Technical Service Providers (TSPs) are individuals or businesses certified to help agricultural producers plan and apply conservation practices on their land. There is a growing demand for TSP’s with a variety of specialized skills in conservation planning and design. To become a certified TSP with NRCS, register and submit an application describing your qualifications for approval through our online directory.

Register as a TSP.

Irrigation Hydropower Technical Guide

Presented within, service providers can find, technical manuals, templates, forms and documentation needed to complete a small hydropower irrigation project. To aid in the project development are examples and case studies.

Agricultural Hydropower Technical Manual

Hydropower Toolbox

- Hydro-Mechanical

- Hydroelectric

Hydro-Mechanical vs. Hydroelectric

Hydropower is defined as power derived from the energy of falling and running water. The RCPP program focuses on two types of hydropower projects, hydro-mechanical systems, and hydroelectric systems. They share many of the main components, but the systems differ in many ways. Hydropower systems require little maintenance and have low operating costs. In general, turbines are very reliable and durable. These systems are gaining popularity in the agriculture community because of their ability to not only save the producer electric power expenses but also reduce carbon emissions and other greenhouse gases by not burning oil or natural gas to power the irrigation systems.

Hydro-Mechanical Systems

Hydro-mechanical systems convert available head and flow of water into mechanical energy to power machinery, specifically hydraulically powered center pivot sprinkler systems. This type of system is only possible given adequate site conditions and appropriate equipment. The center pivot must be a “hydraulically powered center pivot” meaning that the drive system is powered with a hydraulic pump unit as opposed to an electric motor.

Sites without cost-effective access to a power line and with access to gravity pressurized water are best suited for this application. Annual operating costs of electricity or fuel are eliminated when converting to a hydro-mechanical system.

Hydroelectric Systems

Hydroelectric systems installed on pressurized irrigation pipelines are designed to directly offset electrical loads for agricultural operations in a grid-connected, net-metered system (less than 50 kw, depending on the restrictions of the local utility). Hydroelectric systems use the available head and flow of water to convert energy into electricity. The turbine is used to rotate a generator that produces either DC or AC electricity. A package of electrical equipment and controls is used to safely transfer electricity to a local electric load or a connection with the power line. Hydroelectric projects should be considered if the project has access to a power line and there are electrical loads that can be offset.

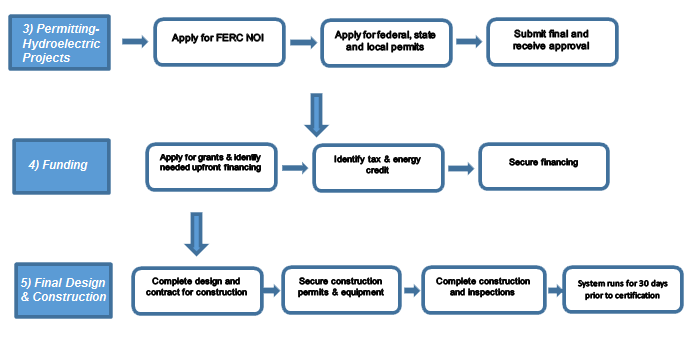

The first step in developing any hydropower project is to complete a Site Assessment. The purpose of a Site Assessment is to determine if a proposed project site appears promising enough to warrant proceeding to a Feasibility Assessment.

A Technical Report including a feasibility study looks at the potential project in more detail than the Site Assessment. The purpose is to gather enough information and perform enough design tasks to decide if the potential project is both technically and economically feasible.

Hydro-mechanical: Feasibility is straightforward. If the appropriate site conditions exist, i.e. enough excess pressure or flow to produce sufficient power for the center pivot, then the project is technically feasible. If the project is technically feasible, it is also likely economically feasible, since installing and operating a hydro-mechanical system costs less than a diesel generator or electrical grid connection and eliminates annual energy costs.

Hydroelectric: Feasibility is more complicated. These are many different possible configurations, many turbines, and several additional costs to consider. In general, assessing the feasibility of a hydropower project requires investigation, planning, and performance of the following items:

- Resource Assessment

- Project Layout and Conceptual Design

- Evaluate utility approval as part of the interconnection feasibility.

- Economic Analysis

- Review permitting process

Hydro-mechanical: The design of a hydro-mechanical system requires the designer to understand how turbines and hydraulic pump units operate. The system design includes the following elements if the intake and penstock already exist as part of the irrigation system pipeline.

- Turbine Selection

- Bypass Design

- Layout including valves, rotation, and fittings

Hydroelectric: The complete design of a hydroelectric project involves civil, mechanical, and electrical engineering. All three are disciplined are represented in any project and the design systems must meet the same requirements as a PV solar system and requires the certification of an engineer.

- Intake

- Penstock

- * Powerhouse and Foundation

- Turbine and Generator

- Controls and Interconnection

Partner Resources

Colorado State Conservation Board

Colorado Water Conservation Board

Colorado State University Extension

Colorado Association of Conservation Districts

Colorado Rural Electric Association

Colorado Small Hydro Association

The Nature Conservancy of Colorado