Egg Producers

Click on any of the topics listed below to expand or minimize the section.

- Small Flock Egg Producers

If you plan to sell fewer than 250 dozen eggs per month of your own flock's eggs on the farm, at a farmer's market, or through a community-supported agricultural organization or similar venue, then you are exempt from licensing by the Colorado Department of Agriculture (CDA).

All eggs offered for sale must be washed according to the guidelines found below. All eggs offered for sale must be kept under refrigeration between 33°F and 41°F.

Eggs sold at farmers' markets, community-supported agricultural organizations, and similar venues must be transported in a clean and sanitary environment between 33°F and 41°F. The egg packages must be labeled with:

- The address where the eggs originated

- The packaging date

- If not treated for salmonella, such as by pasteurization, they must be labeled with "Safe Handling Instructions: To prevent illness from bacteria, keep eggs refrigerated, cook eggs until yolks are firm, and cook any foods containing eggs thoroughly."

- And labels must also include "These eggs do not come from a government-approved source."

If your flock size is under 3,000 domesticated chicken hens, and you wish to sell your eggs to a grocery store, restaurant, or other institution, then a Class I Egg Producer license is required and your operation will be inspected. CDA inspects the processing of the eggs for good manufacturing practices and complete labeling on cartons of eggs.

A commercial kitchen is not required for processing small-flock producers' eggs, but the processing area and the refrigerator or cooler must be clean and sanitary. CDA inspectors will not inspect the housing of the hens or ask about your feeding or gathering practices.

An on-farm small-flock egg producer inspection involves:

- Checking the washing and sanitizing of the eggs to ensure that the eggs are free from any substance or condition that could adulterate or adversely affect the wholesomeness or quality of the eggs by absorption of bacteria or odors.

- Verification that all eggs are candled and graded before being packed; the inspector will also verify that your candling device is sufficient.

- Inspection of the storage and transportation coolers in use, and that the eggs are stored and transported in a sanitary environment between 33°F and 41°F.

All licensed Class I Egg Producers must store and transport eggs in a clean and sanitary environment between 33°F and 41°F, and use clean cartons which do not have any previous producer's identification on them. The cartons must be properly labeled by the producer with the following items:

- Accurate Grade (AA, A, or B)

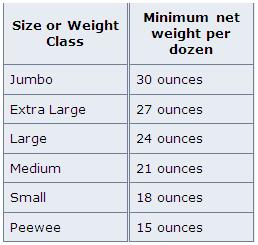

- Size (Peewee, Small, Medium, Large, Extra Large or Jumbo)

- Packing Date, and

- Business name and address

- No expiration date is required; but if one is used, it may only be 30 days past the pack date

The Colorado Retail Food Establishment Rules and Regulations may also require egg sellers to hold a retail food establishment license. Please contact CDPHE Retail Food Program for more information.

Details are found below on the washing, sanitizing, candling, grading, labeling, and storage of small flock producers' eggs.

- Washing & Sanitizing Eggs

Dirty eggs can be a health hazard if they are not properly cleaned and sanitized. Dirty eggs should be washed using an unscented dishwashing liquid or another food-grade detergent. Water temperature should be no less than 110°F and no more than 120°F. For information on USDA-approved egg-washing compounds, go to the Nonfood Compounds Listing Directory and look for Shell Egg information under Q1.

After washing the eggs, they should be sanitized by dipping or spraying using a chlorinated or hydrogen peroxide solution. To dip, make up a basin containing 1 to 2 gallons of 120°F water and bleach at 100-200 PPM chlorine. A 200 PPM chlorine solution can be made by mixing 1 tablespoon of bleach with 1 gallon of water. To spray eggs, a spray bottle with 120°F water and bleach at 100-200 PPM is good. If eggs are to be used for retail sales, a chemical method of sanitization should be used. For guidance from the FDA on sanitizing shell eggs, go to the Egg Safety Page from the FDA.

The United States Department of Agriculture (USDA) Food Safety and Inspection Service (FSIS) has published a page on the safe handling of shell eggs. Go to the Egg Safety Page from the FSIS to find more information.

- Candling Eggs

All eggs destined for sale off-farm must be candled using a device sufficient to view the interior of the egg. A commercial candler is a specially made light projector for this purpose, but a homemade candler may also be used. Meat spots, blood spots, and cracked egg shells can be viewed only by candling. Any egg that is defective should not be distributed for sale.

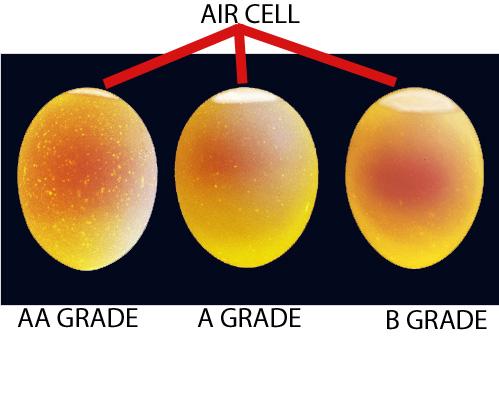

Candling eggs is the best way to find the size of the air cell, and thereby determine the quality grade of the egg.

- Grading Eggs

Before being sold in Colorado, all eggs shall be graded into Colorado consumer grades and weight classes which are based on USDA standards of quality. The grade of an egg is a guarantee of quality, AA being the highest. The grade is most easily determined by candling to gauge the size of the air cell in the large end of the egg. Go to the USDA Egg Grading Page to download their manual.

An egg with a small air cell is of higher quality than an egg with a larger air cell. When an egg is first laid, there is no air cell but as time goes on and the egg cools, an air cell forms and continues to grow in size because of the pores in the egg shell itself. The air cell can be measured by using an air cell gauge, which is a card that is held up to the egg while candling. An example of an air cell gauge can be seen below.

- Sizing Eggs

The size class of a dozen eggs can be determined by weighing them. Use the chart below to classify your flock’s eggs:

- Labeling Eggs

Each package of eggs must be labeled with the following information:

- The producer/packer’s name and address. The address must include a zip code. The CDA license number is an optional label item that may be in addition to the name and address.

- The date of packing. The pack date may be expressed as the Julian date (numbered day of the year) or as the MONTH/DAY the eggs were packed.

- The grade of the eggs. This will be either an AA, A, or B grade.

- The size of the eggs. This may be determined by weighing the eggs; refer to the chart for these size designations.

- The expiration date is not required, but it is optional. If eggs are labeled with an expiration date, it may be no more than 30 days past the pack date, and must be expressed with “EXP MONTH/DAY” or "SELL BY MONTH/DAY".

- The FDA requires all cartons of shell eggs that have not been treated to destroy Salmonella must carry the following safe handling statement, “Safe Handling Instructions: To prevent illness from bacteria, keep eggs refrigerated, cook eggs until yolks are firm, and cook foods containing eggs thoroughly.

- Storing and Transporting Eggs

All eggs destined for sale off-farm must be stored between 33°F and 41°F. They also must be transported in a clean and sanitary environment and maintained at this temperature while being offered for sale.

- Applying For An Egg Producer License

You may complete the fillable PDF form online and then print it out, or print out the Egg Producer / Dealer License Application and then fill it out by hand. Fill in all the information in the spaces provided. If you are a small-flock egg producer with fewer than 3,000 birds, complete the Producer Questionnaire on the 2nd page of the application. Submit the application with the Class I License fee to the address shown on the application. Upon approval, the license will be issued. An inspector will contact you for an inspection.